Aluminum Square Profiles

Introduction:

Aluminum square profiles have become indispensable in various industries due to their versatility, durability, and strength. These profiles, made from aluminum alloys, offer a wide range of applications in construction, automotive, aerospace, and many other fields. In this article, we will explore the characteristics and uses of aluminum square profiles, highlighting their unique properties that make them a preferred choice in modern engineering.

Composition and Characteristics:

Aluminium square profiles are typically made from aluminum alloys, which are carefully engineered to enhance specific properties such as strength, corrosion resistance, and formability. The most common alloy used for these profiles is 6061, known for its excellent combination of strength and workability. Other alloys, like 6063, are also employed to achieve different performance characteristics.

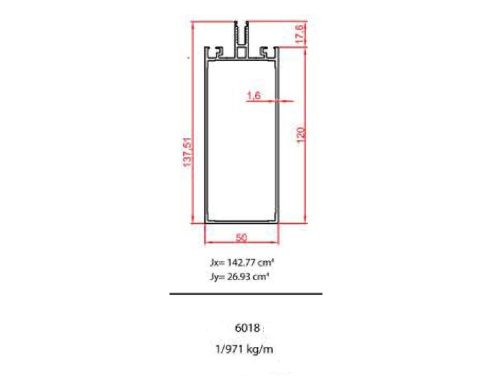

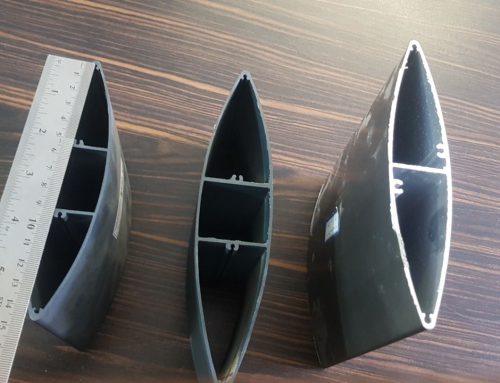

The square shape of these profiles adds to their structural integrity, providing stability and support in various applications. The extrusion process is commonly used to manufacture aluminum square profiles, allowing for the creation of consistent shapes with precise dimensions.

Key Properties:

- Lightweight: Aluminum is renowned for its low density, making square profiles significantly lighter than many other construction materials. This characteristic is particularly beneficial in industries where weight reduction is crucial, such as aerospace and automotive.

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer, rendering it highly resistant to corrosion. This property makes aluminum square profiles an excellent choice for outdoor applications or environments where exposure to moisture and other corrosive elements is a concern.

- High Strength-to-Weight Ratio: Despite its lightweight nature, aluminum boasts an impressive strength-to-weight ratio. This makes aluminum square profiles ideal for applications where both strength and weight considerations are paramount, such as in the construction of structural components.

- Formability: The extrusion process allows for the creation of complex and precise shapes. Aluminum square profiles can be customized to meet specific design requirements, offering engineers and designers a high level of flexibility.

Applications:

Construction: Aluminium square profiles find widespread use in the construction industry. They are employed in the creation of frames, support structures, and architectural elements due to their combination of strength and lightness.

Transportation: In the automotive and aerospace industries, aluminum square profiles are used to manufacture lightweight yet strong components. This contributes to fuel efficiency in vehicles and improves overall performance.

Electronics: The electrical conductivity of aluminum makes it suitable for use in electronic components. Square profiles are utilized in the construction of heat sinks, frames, and enclosures in electronic devices.

Furniture and Decor: The aesthetic appeal of aluminum, coupled with its durability, makes aluminum square profiles a popular choice in the manufacturing of modern furniture and decorative elements.

Solar Energy: In the renewable energy sector, aluminum square profiles play a crucial role in the construction of solar panel frames and support structures. The corrosion-resistant nature of aluminum ensures the longevity of these components, contributing to the overall sustainability of solar power systems.

Marine Industry: The marine environment, with its constant exposure to saltwater and harsh weather conditions, demands materials with excellent corrosion resistance. Aluminum square profiles are utilized in boat construction, marine infrastructure, and offshore applications, where their durability and resistance to rust make them an ideal choice.

Medical Equipment: Aluminum’s hygienic properties, coupled with its lightweight and durable nature, make it suitable for various medical applications. Aluminum square profiles are used in the manufacturing of medical equipment, including bed frames, support structures, and components for diagnostic devices.

Automated Machinery: In the manufacturing sector, especially in the production of automated machinery, aluminum square profiles are favored for their ability to provide structural support while keeping the overall weight of the equipment manageable. This is particularly important in industries where precision and efficiency are paramount.

Custom Fabrication: The formability of aluminum square profiles allows for custom fabrication to meet specific project requirements. Whether it’s creating unique architectural designs or developing specialized components for a particular application, the versatility of aluminum profiles enables engineers and designers to bring their ideas to life.

Recyclability: An additional environmental benefit of aluminum is its recyclability. Aluminum square profiles can be recycled repeatedly without losing their inherent properties. This makes aluminum a sustainable choice for industries aiming to reduce their environmental footprint and promote circular economy practices.

Maintenance and Cost Benefits: Beyond their initial cost, aluminum square profiles offer long-term benefits in terms of maintenance. The corrosion-resistant properties reduce the need for frequent upkeep, making them a cost-effective choice over the life cycle of a project. This aspect is particularly crucial in industries where downtime and maintenance costs can have a significant impact on overall operations.

Thermal Conductivity: Aluminum’s excellent thermal conductivity is an advantageous property in various applications. In industries where heat dissipation is critical, such as electronics and automotive manufacturing, aluminum square profiles are used to create effective heat sinks and dissipate thermal energy efficiently.

Global Adoption and Standardization: The adoption of aluminum square profiles is not confined to specific regions. Their popularity is a global phenomenon, leading to standardized manufacturing processes and specifications. This standardization promotes interchangeability of components and facilitates a seamless integration of aluminum profiles into diverse projects worldwide.

Technological Advancements: Ongoing research and development in metallurgy and manufacturing techniques continue to enhance the properties of aluminum alloys. Technological advancements contribute to the creation of even stronger, more lightweight, and corrosion-resistant aluminum square profiles, opening up new possibilities for engineering applications.

Challenges and Innovations: While aluminium square profiles offer numerous advantages, challenges such as potential fatigue and stress issues must be addressed. Ongoing innovations in alloy formulations and manufacturing processes aim to overcome these challenges, ensuring that aluminum remains at the forefront of modern engineering solutions.

Environmental Impact: The use of aluminum in various industries aligns with the global push towards sustainability. Aluminum is not only recyclable but also requires less energy to recycle compared to its initial production. As industries strive to reduce their environmental impact, the eco-friendly attributes of aluminum square profiles contribute to greener and more responsible manufacturing practices.

Future Trends and Innovations: Looking ahead, the future of aluminum square profiles holds exciting prospects. Researchers and engineers are exploring novel applications and pushing the boundaries of what is achievable with this versatile material. Nanotechnology and advanced surface treatments may further enhance the properties of aluminum, opening doors to unprecedented applications and performance improvements.

Integration with Smart Technologies: As industries embrace smart technologies and the Internet of Things (IoT), aluminum square profiles can play a role in the integration of sensors and other smart components. The lightweight and formable nature of aluminum make it an ideal material for constructing frames and housings for various sensor technologies, contributing to the development of smarter, more connected systems.

Educational and Research Initiatives: Educational institutions and research organizations continue to focus on aluminum alloys and their applications. These initiatives aim to train the next generation of engineers and researchers, fostering a deeper understanding of aluminum’s properties and its potential contributions to sustainable and innovative solutions.

Collaboration Across Industries: The versatility of aluminium square profiles encourages collaboration between industries. Cross-industry partnerships facilitate the exchange of knowledge and best practices, leading to the development of hybrid solutions that leverage the strengths of aluminum in combination with other materials and technologies.

Global Regulations and Standards: As environmental concerns grow, governments and international bodies are likely to introduce more stringent regulations regarding material usage and waste management. Aluminum’s recyclability and low environmental impact position it favorably in the face of evolving standards, driving industries towards sustainable practices.

User-Friendly Design Tools: With advancements in design software and simulation tools, engineers and designers can more efficiently incorporate aluminum square profiles into their projects. User-friendly interfaces and simulation capabilities empower professionals to explore various design options, ensuring optimal use of aluminum in terms of both performance and cost-effectiveness.

Continued Market Growth: The global demand for aluminium square profiles is expected to continue its upward trajectory. As emerging economies undergo rapid industrialization and established industries seek more sustainable alternatives, the market for aluminum profiles is likely to expand, creating new opportunities and challenges for manufacturers and end-users alike.

The Role of Research and Development: Ongoing research and development initiatives are essential for unlocking the full potential of aluminum square profiles. Investment in materials science, metallurgy, and manufacturing processes will likely lead to the discovery of new alloys and fabrication techniques, further enhancing the properties of aluminum and expanding its range of applications.

Addressing Environmental Concerns: Environmental sustainability is a growing priority across industries. Manufacturers and end-users of aluminium square profiles are increasingly focusing on minimizing their ecological footprint. This may involve not only recycling practices but also exploring ways to reduce energy consumption during the production and processing of aluminum.

Integration into Circular Economy Models: Aluminum’s recyclability makes it an excellent candidate for a circular economy model. As industries move towards circularity, aluminum square profiles can play a vital role in closed-loop systems, where materials are reused, remanufactured, and recycled to minimize waste and environmental impact.

Customization and Tailored Solutions: The demand for customized and tailor-made solutions continues to rise. Aluminium square profiles, with their formability and versatility, enable engineers and designers to create bespoke components for specific applications. This trend is likely to grow as industries seek more efficient and specialized solutions.

Challenges and Resilience: Despite its many advantages, the aluminum industry faces challenges such as volatile raw material prices and geopolitical factors affecting the supply chain. Resilience and adaptability will be crucial as the industry navigates these challenges, and innovations in sourcing, production, and distribution are expected to play a role in overcoming these hurdles.

Education and Skill Development: As the use of aluminum square profiles expands, there is a growing need for skilled professionals who understand the intricacies of working with this material. Educational programs and skill development initiatives will be vital in ensuring a workforce that is well-equipped to harness the full potential of aluminum in various applications.

Global Collaboration for Sustainability: Sustainable practices require global cooperation. Collaboration between industries, governments, and international organizations is essential for setting and achieving sustainability goals. Sharing best practices, technologies, and research findings can accelerate the adoption of environmentally friendly approaches to aluminum production and usage.

Consumer Awareness and Preferences: Increasing awareness among consumers about the environmental impact of materials is influencing purchasing decisions. Aluminum’s eco-friendly characteristics position it favorably in the eyes of environmentally conscious consumers, driving industries to prioritize the use of sustainable materials like aluminum square profiles.

Regulatory Support and Standards: Governments and regulatory bodies play a pivotal role in shaping the landscape for materials like aluminum. Supportive policies, incentives for sustainable practices, and the establishment of standards for the use and recycling of aluminum contribute to a conducive environment for the growth of the aluminum industry.

Beyond Earth: Extraterrestrial Applications: As humanity explores space and considers the possibility of establishing colonies on other planets, the qualities of aluminium square profiles become even more relevant. The lightweight nature of aluminum could prove crucial in spacecraft construction, while its resistance to corrosion makes it a suitable candidate for structures in extraterrestrial environments.

Digital Twin Technology Integration: The integration of digital twin technology with aluminum square profiles allows for real-time monitoring, simulation, and optimization of structures. This innovation enhances predictive maintenance capabilities, ensuring the longevity and safety of applications using aluminum profiles.

Cross-Industry Synergies: Synergies between seemingly disparate industries continue to drive innovation. The exchange of knowledge and technologies between sectors, such as aerospace and automotive or construction and electronics, may lead to unexpected breakthroughs in the application and processing of aluminium square profiles.

Artificial Intelligence in Design: The application of artificial intelligence (AI) in design processes is transforming how engineers approach projects. AI algorithms can analyze vast datasets and suggest optimized designs for structures using aluminum square profiles, improving efficiency and potentially uncovering new design possibilities.

Emerging Markets and Sustainable Development: Emerging markets are likely to witness increased adoption of aluminum square profiles as they seek sustainable development solutions. The versatility, recyclability, and lightweight characteristics of aluminum make it an attractive choice for nations aiming to balance industrial growth with environmental responsibility.

Humanitarian and Disaster Relief Efforts: Aluminum’s portability and versatility make it valuable in humanitarian and disaster relief efforts. From quickly assembling shelters to constructing temporary bridges, aluminum square profiles can play a vital role in providing rapid and effective solutions in times of crisis.

Inclusive Design for Accessibility: The formability of aluminum square profiles facilitates the creation of structures and components that adhere to principles of inclusive design. This ensures that products and infrastructure, including ramps, handrails, and assistive devices, are accessible to people with diverse abilities.

Continued Material Advancements: Continued advancements in material science may lead to the development of even more advanced aluminum alloys. These alloys could exhibit enhanced strength, durability, and other specialized properties, opening up new frontiers for the use of aluminum square profiles in cutting-edge applications.

Global Resilience and Supply Chain Security: The importance of resilient supply chains has been underscored by global events. Industries will likely prioritize supply chain security, including the sourcing of raw materials like aluminum. Diversification of suppliers and the development of local manufacturing capabilities may become key strategies.

A Call for Innovation and Collaboration: In the dynamic landscape of materials engineering, aluminum square profiles stand as a testament to human ingenuity and innovation. The call for continuous improvement, sustainable practices, and global collaboration echoes through the aluminum industry, challenging stakeholders to shape a future where aluminum remains a cornerstone of progress.

The Role of Consumer Consciousness: With an increasing emphasis on sustainability, consumer consciousness plays a vital role in shaping the future of aluminum square profiles. As consumers become more informed about the environmental impact of their purchases, industries are prompted to adopt eco-friendly practices and transparent supply chains, further reinforcing the demand for sustainable materials like aluminum.

Circular Economy and Closed-Loop Systems: The principles of the circular economy are gaining traction, emphasizing a closed-loop system where materials are reused, recycled, and repurposed. Aluminum square profiles align seamlessly with this philosophy, contributing to the development of sustainable and closed-loop manufacturing practices across various sectors.

Educational Outreach and Public Awareness: Educating the public about the benefits of aluminum, its recyclability, and its diverse applications is crucial. Public awareness campaigns and educational outreach programs can foster a deeper understanding of the role that aluminum square profiles play in sustainable development and technological progress.

Government Incentives and Policies: Governments worldwide are recognizing the importance of sustainable materials and are implementing policies and incentives to encourage their use. Incentives for recycling, tax credits for sustainable practices, and regulations promoting eco-friendly construction materials all contribute to the widespread adoption of aluminum square profiles.

Adapting to Unforeseen Challenges: The global landscape is subject to unforeseen challenges, from economic shifts to geopolitical events. The adaptability of industries working with aluminum square profiles will be tested in navigating these challenges, requiring resilience, innovation, and strategic planning to ensure the continued growth and stability of the sector.

Community Engagement and Social Impact: The social impact of industries utilizing aluminum extends beyond economic considerations. Community engagement initiatives, responsible sourcing of materials, and ethical manufacturing practices contribute to a positive social impact, fostering goodwill and sustainable development in the regions where aluminum-related activities are conducted.

Open Innovation Platforms: Open innovation platforms that encourage collaboration between industry players, research institutions, and startups can spur breakthroughs in aluminum-related technologies. These platforms facilitate the exchange of ideas, expertise, and resources, accelerating the pace of innovation and pushing the boundaries of what is achievable with aluminum square profiles.

Public-Private Partnerships: Collaborative efforts between public and private entities are instrumental in advancing the use of aluminum square profiles. Governments and industry stakeholders working together can create favorable conditions for research, investment, and the development of infrastructure that supports the growth of aluminum-related industries.

Celebrating Achievements and Milestones: Acknowledging and celebrating milestones in the use of aluminum square profiles serves not only to recognize achievements but also to inspire further innovation. Recognizing the individuals, companies, and projects that push the boundaries of what is possible with aluminum encourages a culture of excellence and continuous improvement.

A Vision for a Sustainable Future: In envisioning the future of aluminum square profiles, a commitment to sustainability, innovation, and responsible stewardship of resources stands out. The journey of aluminum is intertwined with the story of human progress, and as we look ahead, it is a shared responsibility to ensure that this versatile material continues to contribute to a sustainable and resilient future.

Closing Remarks: The story of aluminum square profiles is a narrative of adaptability, innovation, and the pursuit of sustainable solutions. As we navigate an ever-evolving world, the role of aluminum in shaping the future of engineering and manufacturing remains central. The journey is ongoing, and with each chapter, we uncover new possibilities, face fresh challenges, and collectively contribute to a future where aluminum continues to be a symbol of progress, versatility, and sustainable development.

Leave A Comment