Machine rail

Machine rails play a crucial role in the operation of retractable roof systems. They provide the necessary guidance and support for the moving parts of the roof, ensuring smooth and reliable operation. There are several types of machine rails used in retractable roof systems, each with its own advantages and disadvantages.

Types of Machine Rails

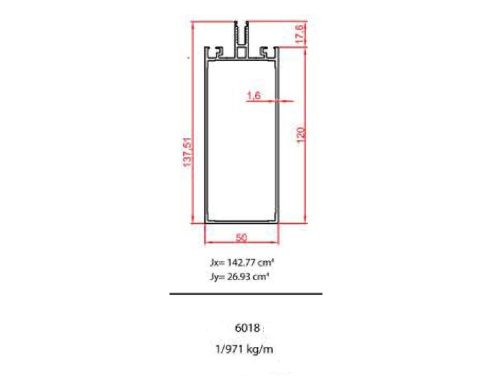

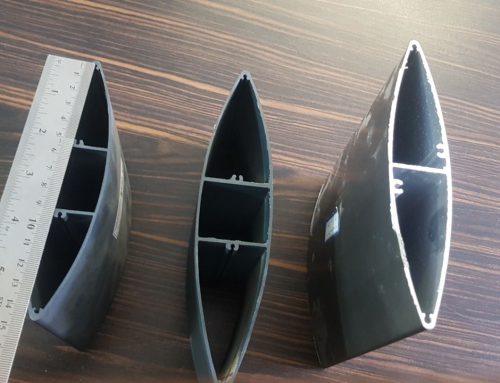

- Linear rails: These are the most common type of machine rail used in retractable roof systems. They are made of high-strength steel and have a smooth surface that allows the roof panels to slide easily. Linear rails are available in a variety of sizes and can be custom-designed to meet the specific needs of a retractable roof system.

- V-shaped rails: These rails are shaped like a V, with a groove that runs the full length of the rail. The roof panels ride in the groove, which helps to keep them aligned and prevent them from slipping. V-shaped rails are often used in conjunction with linear rails to provide additional stability.

- Round rails: These rails are made of a round bar of steel and are supported by bearings. They are less common than linear or V-shaped rails, but they can be used in applications where a high degree of precision is required.

Advantages of Machine Rails

- Smooth operation: Machine rails help to ensure that the retractable roof panels slide smoothly and easily, without any binding or sticking. This is important for preventing wear and tear on the roof system and for ensuring its long-term performance.

- Reduced noise: Machine rails can help to reduce the noise generated by a retractable roof system. This is because they provide a smooth surface for the roof panels to slide on, which helps to minimize friction and vibration.

- Increased safety: Machine rails can help to improve the safety of a retractable roof system by preventing the roof panels from falling or collapsing. This is because they provide a secure and stable platform for the roof panels to rest on.

- Long lifespan: Machine rails are made of durable materials and are designed to withstand the harsh elements. This means that they can last for many years without needing to be replaced.

Challenges of Machine Rails

- Cost: Machine rails can be expensive to purchase and install. This is especially true for large retractable roof systems.

- Maintenance: Machine rails require regular maintenance to ensure that they continue to function properly. This includes cleaning, lubrication, and inspection.

- Design: The design of the machine rails must be carefully considered to ensure that they are compatible with the retractable roof system. This is important for preventing problems such as binding, sticking, and noise.

Choosing the Right Machine Rail

The type of machine rail that is best for a particular retractable roof system will depend on a number of factors, including the size and weight of the roof panels, the amount of use the roof will receive, and the budget. It is important to consult with a qualified engineer to determine the best type of machine rail for a specific application.

Machine Rail Materials and Coatings

Machine rails are typically made of high-strength steel, but other materials can also be used, such as aluminum, stainless steel, and even polymers. The choice of material will depend on the specific requirements of the application.

- Steel: Steel is the most common material for machine rails because it is strong, durable, and relatively inexpensive. However, steel rails can be susceptible to rust and corrosion, so they must be properly coated.

- Aluminum: Aluminum is a lighter and more corrosion-resistant alternative to steel. However, it is not as strong as steel, so it is not suitable for all applications.

- Stainless steel: Stainless steel is the most corrosion-resistant material available for machine rails.

- Polymers: Polymers are a relatively new material for machine rails. They are lightweight, corrosion-resistant, and can be made to be very smooth. However, they are not as strong as steel or aluminum, and they can be susceptible to wear and tear.

In addition to the material, the type of coating that is applied to the machine rail is also important. The coating helps to protect the rail from corrosion and wear, and it can also improve the smoothness of the rail surface. Some common types of coatings for machine rails include:

- Zinc plating: Zinc plating is a common coating for steel machine rails. It is relatively inexpensive and provides good corrosion protection.

- Nickel plating: Nickel plating is more expensive than zinc plating, but it provides better corrosion protection.

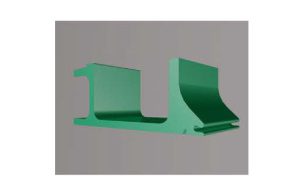

- Powder coating: Powder coating is a durable coating that can be applied to a variety of materials, including steel, aluminum, and stainless steel.

- Anodizing: Anodizing is a process that creates a protective oxide layer on the surface of aluminum. This oxide layer is very resistant to corrosion and wear.

Machine Rail Installation

The installation of machine rails is a critical step in the construction of a retractable roof system. The rails must be installed correctly to ensure that the roof panels slide smoothly and safely. Here are some of the important steps involved in the installation of machine rails:

- Preparation: The first step is to prepare the surface where the rails will be installed. This may involve cleaning the surface, leveling it, and applying a primer.

- Mounting: The rails are then mounted to the supporting structure using brackets or bolts. The spacing between the rails will depend on the size and weight of the roof panels.

- Alignment: The rails must be carefully aligned to ensure that the roof panels will slide smoothly. This can be done using a laser level or other measuring tools.

- Fastening: Once the rails are aligned, they are fastened to the supporting structure using nuts and bolts.

- Inspection: The final step is to inspect the installation to ensure that it meets all of the necessary specifications.

Machine Rail Maintenance

Machine rails require regular maintenance to ensure that they continue to function properly. This includes cleaning, lubrication, and inspection.

- Cleaning: Machine rails should be cleaned regularly to remove dirt, debris, and other contaminants. This can be done using a mild soap and water solution.

- Lubrication: Machine rails should be lubricated regularly to reduce friction and wear. The type of lubricant that is used will depend on the material of the rails.

- Inspection: Machine rails should be inspected regularly for signs of wear and tear. This includes checking for cracks, rust, and other damage.

Machine Rail Specifications and Standards

Machine rails must meet certain specifications and standards to ensure their safety and performance. These specifications and standards are typically set by national or international organizations, such as the American Society of Mechanical Engineers (ASME) or the International Organization for Standardization (ISO).

Some of the important specifications and standards for machine rails include:

- Material: The material of the machine rail must be strong enough to support the weight of the roof panels. It must also be resistant to corrosion and wear.

- Dimensions: The dimensions of the machine rail must be precise to ensure that the roof panels fit properly.

- Surface finish: The surface finish of the machine rail must be smooth to prevent the roof panels from sticking or binding.

- Straightness: The machine rail must be straight to ensure that the roof panels slide smoothly.

- Flatness: The machine rail must be flat to ensure that the roof panels are level.

- Hardness: The machine rail must be hard enough to resist wear and tear.

- Fatigue strength: The machine rail must be strong enough to withstand the repeated stresses of opening and closing the roof.

In addition to these specifications, machine rails must also comply with certain safety standards. These standards are designed to protect workers from injury.

Here are some of the safety standards that apply to machine rails:

- ANSI/ASME B15.1-2017: Safety Standard for Power Transmission Roller Chains, Sprockets, Attachments, and Chain Drives

- ANSI/ASME B11.19-2010: Performance Requirements for Machine Tool Spindles and Spindle Extensions

- ISO 12100:2010: Safety of machinery – General principles for design – Risk assessment and risk reduction

- ISO 14121-1:2007: Safety of machinery – Guards – Part 1: General requirements

- ISO 14121-2:2012: Safety of machinery – Guards – Part 2: Fixed guards

- ISO 14121-3:2018: Safety of machinery – Guards – Part 3: Movable guards

By complying with these specifications and standards, manufacturers can ensure that their machine rails are safe and reliable.

Future of Machine Rails

The future of machine rails is bright. There are a number of new technologies that are being developed that could make machine rails even more efficient and effective.

Some of the most promising technologies include:

- Self-lubricating materials: These materials are designed to release a lubricant automatically, reducing the need for manual lubrication.

- Anti-friction coatings: These coatings are designed to reduce friction between the machine rail and the roof panels, improving the efficiency of the system.

- Magnetic levitation: This technology uses magnets to levitate the roof panels, eliminating the need for contact between the panels and the machine rail.

- Smart sensors: These sensors can monitor the condition of the machine rail and alert maintenance personnel to potential problems.

These technologies have the potential to improve the performance and lifespan of machine rails, making them even more valuable in the construction of retractable roof systems.

Conclusion

Machine rails are a critical component of retractable roof systems. They play a vital role in ensuring the smooth and reliable operation of the roof. By understanding the different types of machine rails, their advantages and disadvantages, and the challenges of using them, you can choose the right machine rails for your specific application. By following the proper installation and maintenance procedures, you can ensure that your machine rails last for many years to come. With the development of new technologies, the future of machine rails is bright.

Leave A Comment