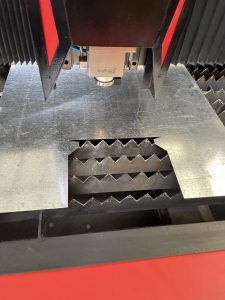

Laser cutting aluminium plate

Laser cutting has revolutionized the way we cut and shape metals, particularly aluminium. The ability to precisely cut aluminium plates using laser technology has opened up new possibilities in the manufacturing industry. In this article, we will explore the advantages and challenges of laser cutting aluminium plates, the different types of laser cutting techniques available, and the factors to consider when laser cutting aluminium plates.

Advantages of Laser Cutting Aluminium Plates

Laser cutting has several advantages over traditional cutting methods such as sawing, shearing, and punching. Some of these benefits include:

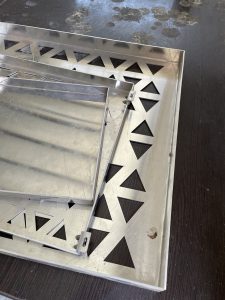

- Precision: Laser cutting produces precise cuts with very tight tolerances, ensuring accuracy in the final product. This accuracy is particularly useful when dealing with intricate designs, thin materials, or complex shapes.

- Speed: Laser cutting is a fast and efficient process that can cut through aluminium plates quickly and with little to no post-processing required.

- Versatility: Laser cutting can cut through various thicknesses of aluminium plates, ranging from thin sheets to thick plates.

- Cleanliness: Laser cutting produces clean and accurate cuts without any burrs or rough edges, reducing the need for further finishing.

- Reduced waste: The precision of laser cutting results in minimal material waste, making it an efficient and cost-effective process.

Challenges of Laser Cutting Aluminium Plates

Despite its many benefits, laser cutting aluminium plates also presents some challenges. These challenges are related to the material’s unique properties, including its high reflectivity, thermal conductivity, and melting point. Here are some of the challenges of laser cutting aluminium plates:

- Reflectivity: Aluminium is highly reflective, which can cause the laser beam to bounce off the surface, reducing cutting efficiency. To overcome this challenge, laser cutting machines use specialized optics and coatings to prevent the laser beam from reflecting.

- Thermal conductivity: Aluminium is an excellent conductor of heat, which means that it can quickly absorb and dissipate heat. This property can cause the material to warp or deform during the cutting process, especially when cutting thicker plates.

- Melting point: Aluminium has a relatively low melting point compared to other metals, which means that it can melt and fuse during the cutting process. This can result in the formation of slag or rough edges, reducing the quality of the final product.

Types of Laser Cutting Techniques for Aluminium Plates

There are several types of laser cutting techniques available for cutting aluminium plates. These techniques differ in their laser sources, beam delivery systems, and cutting processes. Here are some of the most common laser cutting techniques for aluminium plates:

- CO2 Laser Cutting: CO2 laser cutting is the most commonly used technique for cutting aluminium plates. It uses a high-power CO2 laser beam to cut through the material, which is then directed by a series of mirrors and lenses. This technique is ideal for cutting thin to medium thickness aluminium plates.

- Fiber Laser Cutting: Fiber laser cutting is a newer technique that uses a high-power fiber laser beam to cut through aluminium plates. This technique is ideal for cutting thicker aluminium plates and provides faster cutting speeds and higher cutting accuracy than CO2 laser cutting.

- Nd:YAG Laser Cutting: Nd:YAG laser cutting uses a neodymium-doped yttrium aluminum garnet (Nd:YAG) laser beam to cut through aluminium plates. This technique is ideal for cutting thin and thick aluminium plates and provides a higher cutting quality than CO2 laser cutting.

Factors to Consider When Laser Cutting Aluminium Plates

When laser cutting aluminium plates, there are several factors to consider to ensure the best cutting quality and efficiency. These factors include:

- Material thickness: The thickness of the aluminium plate determines the laser cutting technique to use, the laser power required, and the cutting speed.

- Laser power: The laser power required depends on the thickness of the aluminium plate and the desired cutting speed. Higher laser powers are required for thicker plates, but this also increases the risk of warping and deformation.

- Cutting speed: The cutting speed is determined by the laser power and the material thickness. A slower cutting speed can result in higher cutting quality, while a faster speed can increase production rates.

- Gas selection: The choice of gas used during laser cutting can affect the cutting quality and efficiency. Oxygen gas is commonly used for cutting aluminium plates as it reacts with the material, producing a clean cut and reducing the need for post-processing.

- Focusing lens: The choice of focusing lens can affect the precision and quality of the cut. A shorter focal length lens provides higher cutting precision but at the expense of a smaller cutting area.

- Cutting edge quality: The quality of the cutting edge is essential for the final product’s functionality and appearance. Laser cutting produces a clean and precise edge, but the material’s unique properties can cause slag or rough edges.

- Heat management: Proper heat management is crucial during laser cutting to prevent warping and deformation of the material. This can be achieved by using a coolant or reducing the laser power and cutting speed.

Conclusion

Laser cutting aluminium plates has become a popular method in the manufacturing industry due to its many benefits, including precision, speed, versatility, cleanliness, and reduced waste. However, laser cutting aluminium plates also presents some challenges due to the material’s unique properties, including its high reflectivity, thermal conductivity, and low melting point. There are several types of laser cutting techniques available for cutting aluminium plates, including CO2, fiber, and Nd:YAG laser cutting. To ensure the best cutting quality and efficiency, factors such as material thickness, laser power, cutting speed, gas selection, focusing lens, cutting edge quality, and heat management should be considered. With proper planning and execution, laser cutting aluminium plates can provide a fast, efficient, and cost-effective method for producing high-quality metal products.

In addition to its use in the manufacturing industry, laser cutting aluminium plates are also used in other fields, such as automotive, aerospace, and construction. For example, in the automotive industry, laser cutting is used to produce parts such as exhaust systems, engine components, and body panels. In the aerospace industry, laser cutting is used to produce structural components such as brackets, frames, and panels. In the construction industry, laser cutting is used to produce architectural elements such as metal screens, façades, and railings.

To get the most out of laser cutting aluminium plates, it is essential to work with experienced professionals who can provide high-quality laser cutting services. These professionals can offer valuable advice and guidance on the best laser cutting techniques and parameters to use for specific applications. They can also provide a range of value-added services, such as design assistance, prototyping, and post-processing.

In conclusion, laser cutting aluminium plates offer a fast, precise, and cost-effective method for cutting metal plates. Although it presents some challenges due to the material’s unique properties, these can be overcome by using the right laser cutting techniques, parameters, and equipment. When properly executed, laser cutting aluminium plates can produce high-quality metal products with minimal material waste, making it an ideal choice for various applications in the manufacturing, automotive, aerospace, and construction industries.

Leave A Comment