Global Sale and Export of Elliptical (Aerofoil) Louver Profiles

Introduction

Global Sale and Export of Elliptical (Aerofoil) Louver Profiles The architectural world is rapidly shifting toward energy-efficient, sustainable, and visually appealing façade systems. Among these innovations, the elliptical aluminum louver profile—often referred to as the aerofoil louver—has gained remarkable global recognition. Its sleek aerodynamic design provides not only aesthetic value but also superior functionality in shading, ventilation, and temperature regulation. With the rising emphasis on green construction, the sale and export of elliptical louver profiles have become a fast-growing segment in the global building materials market. This article delves into the market dynamics, production technology, export opportunities, and the unique advantages of these architectural components.

Understanding Elliptical (Aerofoil) Louvers

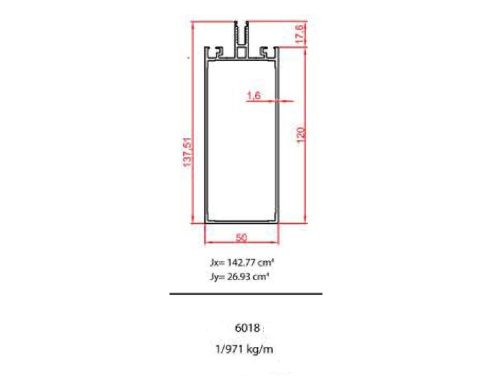

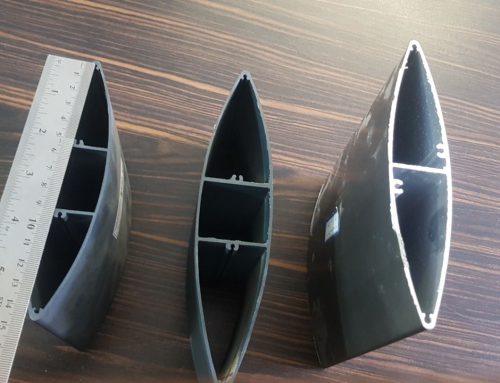

Elliptical louvers are specially designed aluminum profiles with an airfoil cross-section, inspired by the aerodynamic form of an airplane wing. This shape minimizes air resistance while maximizing light diffusion and ventilation. Depending on the design, the louvers can be fixed or adjustable, horizontal or vertical, and manual or motorized. These profiles are typically made from 6063-T5 aluminum alloy, known for its high strength, lightweight nature, and excellent corrosion resistance—qualities that make them ideal for outdoor architectural use.

Architectural Applications Worldwide

The elliptical louver system has found its place in a wide range of architectural projects across the world. From high-rise towers and airports to shopping malls and eco-friendly residential buildings, these louvers serve both functional and decorative purposes. Key applications include:

- Sun control facades: Reducing solar glare and managing daylight penetration inside buildings.

- Natural ventilation systems: Allowing airflow without compromising weather protection.

- Architectural cladding: Creating modern and streamlined building exteriors.

- Skylight shading systems: Regulating light and temperature under glass roofs.

- Parking shelters and walkway roofs: Offering shading and protection in outdoor structures.

This adaptability makes aerofoil louvers an integral component in sustainable architectural design and modern construction projects.

Manufacturing Process and Customization

The production of elliptical aluminum louvers involves advanced extrusion technology to ensure dimensional precision and mechanical strength. After extrusion, the profiles undergo surface treatment such as anodizing or powder coating to enhance durability and visual appeal. Manufacturers offer a wide range of louver sizes, commonly between 100 mm and 450 mm, and customized shapes or colors to suit specific architectural requirements. Profiles can be fabricated into modular systems with hidden frames, motorized pivots, and structural support brackets for quick installation.

Design and Functional Advantages

- Thermal comfort: Reduces heat gain and enhances the building’s energy efficiency.

- Optimized daylight: Provides balanced natural light without glare.

- Noise reduction: The aerodynamic design minimizes wind noise in open environments.

- Low maintenance: The non-corrosive aluminum surface ensures long-lasting performance.

- Enhanced façade aesthetics: Adds a dynamic and futuristic look to any structure.

Export Market Analysis

Global demand for aluminum louver profiles is expanding in regions focusing on urban modernization and environmental sustainability. Export markets such as the Middle East, Central Asia, Europe, and North Africa are showing consistent growth. Countries like Turkey, Qatar, Saudi Arabia, Kazakhstan, and Tajikistan have increased imports of elliptical louvers due to their widespread use in government buildings, hotels, shopping centers, and airports.

Manufacturers that provide comprehensive solutions—ranging from extrusion to system design and on-site consultation—tend to perform better in competitive export markets. Offering technical documents such as structural test reports, CAD drawings, and wind-load resistance certificates significantly improves credibility among international buyers.

Quality Standards and Certifications

To compete in the global market, adherence to international standards is crucial. Leading exporters ensure their profiles comply with EN 755-9, EN 12020-2, or ASTM B221 requirements for aluminum extrusions. Surface treatments should meet Qualicoat and Qualanod certifications, ensuring long-term color retention and corrosion resistance. Additionally, ISO 9001:2015 certification for quality management enhances customer confidence and facilitates entry into regulated markets such as the European Union and North America.

Surface Treatments and Finishes

Surface finishing plays a vital role in the marketability of elliptical louver profiles. Common finishes include:

- Anodized finish: Provides a metallic look with excellent corrosion resistance, ideal for humid and coastal regions.

- Powder coating: Offers a variety of color options, including matte, glossy, and textured finishes.

- Wood-grain hydrographic finish: Combines the warmth of natural wood with the durability of aluminum, popular in luxury buildings.

These treatments enhance both aesthetics and longevity, allowing architects to achieve a perfect balance between form and function.

Logistics and Export Packaging

Proper logistics management is key to ensuring product safety during long-distance shipments. Exporters typically package louvers with bubble wraps, plastic films, and reinforced wooden crates to prevent scratches or deformation. For bulk exports, sea freight in 20-foot or 40-foot containers is the most cost-effective solution. Exporters often provide clients with labeling, documentation, and optional insurance coverage to ensure smooth customs clearance and delivery.

Export Strategies for Global Expansion

To succeed in international markets, companies must combine product quality with strategic business practices. Some effective export strategies include:

- Local partnerships: Collaborate with regional distributors and construction firms for faster market entry.

- Digital marketing: Promote products via professional websites, online catalogs, and architectural platforms like ArchDaily or Houzz.

- Participation in exhibitions: Showcasing products at global events like BAU Munich or The Big 5 Dubai boosts visibility and credibility.

- After-sales service: Offering remote installation guidance and technical training increases long-term customer satisfaction.

Exporters who combine engineering expertise with customer-oriented services position themselves as premium suppliers in the competitive global façade market.

Economic and Environmental Benefits

Exporting aluminum aerofoil louvers contributes to both economic growth and environmental sustainability. Aluminum is 100% recyclable, and using recycled materials during extrusion reduces carbon emissions significantly. Additionally, buildings equipped with louvers consume less energy for air conditioning and lighting, aligning with international green building certifications such as LEED and BREEAM. This dual advantage makes the product not only commercially viable but also environmentally responsible.

Future Trends in the Louver Industry

The next decade will witness a shift toward smart and automated shading systems integrated with building management technologies. Motorized elliptical louvers, equipped with IoT-based sensors, will automatically adjust angles according to sunlight intensity, temperature, and occupancy levels. Furthermore, innovations in lightweight alloys, 3D printing, and nanocoating will further enhance the performance and lifespan of these profiles. Exporters who invest in research and technological integration will maintain a strong competitive edge in the evolving global market.

Conclusion

The sale and export of elliptical aluminum louver profiles are becoming a key pillar of modern façade solutions worldwide. These profiles blend form and function, offering a balance of beauty, energy efficiency, and durability. As international construction projects continue to emphasize sustainability and smart design, the demand for aerofoil louvers will only grow stronger. Manufacturers and exporters who adhere to global standards, innovate in design, and deliver comprehensive customer support will establish lasting success in this high-potential industry. In essence, elliptical louvers are not merely façade components—they represent the evolution of architectural intelligence and environmental harmony.

My partner and I stumbled over here from a different page and thought I might check things out. I like what I see so i am just following you. Look forward to looking into your web page yet again.

whoah this blog is excellent i love reading your articles. Stay up the great paintings! You realize, a lot of persons are looking around for this information, you could aid them greatly.