Curtain wall pricing profile

Curtain walls have become a staple in modern architecture, offering a sleek, efficient, and aesthetically pleasing solution for building envelopes. These non-structural coverings are typically made of lightweight materials like glass, aluminum, or steel, and are designed to withstand wind loads and support their own weight while providing thermal insulation and weather resistance. As such, understanding the pricing profiles associated with curtain walls is crucial for architects, developers, and contractors alike. In this article, we delve into the factors, trends, and considerations that shape curtain wall pricing profiles.

Factors Influencing Pricing:

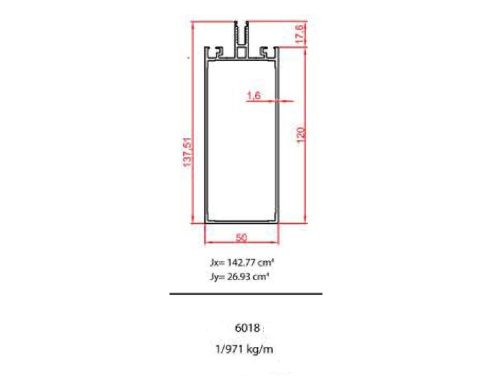

- Material Selection: The choice of materials significantly impacts the cost of curtain walls. Glass, aluminum, and steel are common options, each with its own cost considerations. For instance, high-performance glass with special coatings for thermal insulation will be more expensive than standard glass.

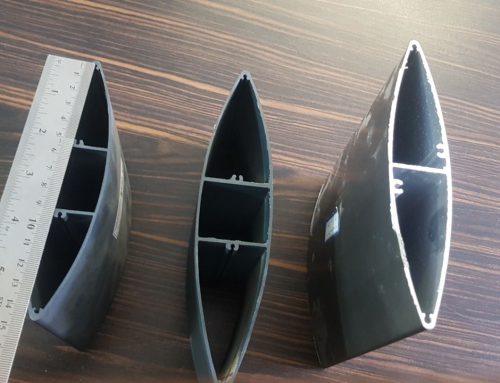

- Design Complexity: The complexity of the curtain wall design directly affects its cost. Intricate designs requiring custom shapes, sizes, or configurations will entail higher fabrication and installation expenses compared to simpler designs.

- Size and Scale: The size and scale of the curtain wall project play a crucial role in determining pricing. Larger projects typically benefit from economies of scale, leading to lower costs per square foot compared to smaller installations.

- Performance Requirements: Curtain walls can be engineered to meet specific performance requirements, such as thermal efficiency, acoustic insulation, and structural integrity. Meeting higher performance standards often entails using specialized materials and manufacturing techniques, which can increase costs.

- Labor Costs: Installation labor costs can vary depending on factors such as location, labor availability, project timeline, and the complexity of installation. Skilled labor for precise installation is essential for ensuring the performance and longevity of the curtain wall system.

Trends in Curtain Wall Pricing:

- Sustainability: With a growing emphasis on sustainable building practices, there is a rising demand for energy-efficient curtain wall systems. This trend has led to the development of innovative, eco-friendly materials and designs, albeit at a potentially higher initial cost.

- Prefabrication: Prefabricated curtain wall systems are gaining popularity due to their efficiency and quality control. While the upfront costs may be higher than traditional stick-built systems, prefabrication can result in faster installation times and reduced labor costs, ultimately offering long-term savings.

- Technological Advancements: Advancements in manufacturing technologies, such as computer-aided design (CAD) and Building Information Modeling (BIM), have streamlined the design and fabrication processes for curtain walls. However, integrating these technologies into the workflow may require additional investment upfront.

- Market Conditions: Fluctuations in material prices, labor rates, and market demand can influence curtain wall pricing. Economic factors, such as inflation and supply chain disruptions, can also impact overall project costs.

Considerations for Curtain Wall Procurement:

- Budget Planning: Establishing a realistic budget early in the project development phase is essential for managing costs effectively. Working closely with architects, engineers, and contractors can help align project requirements with budgetary constraints.

- Value Engineering: Value engineering involves optimizing the cost-performance ratio of curtain wall systems without sacrificing quality or functionality. Identifying cost-saving opportunities through material substitutions, design modifications, or alternative construction methods can help maximize value.

- Quality Assurance: Prioritizing quality assurance throughout the procurement process is crucial for ensuring the longevity and performance of curtain wall systems. Selecting reputable suppliers and contractors with a track record of delivering high-quality installations can mitigate the risk of costly repairs or replacements down the line.

- Lifecycle Costs: While upfront costs are important considerations, it’s essential to evaluate the lifecycle costs of curtain wall systems, including maintenance, repairs, and energy consumption. Investing in durable, energy-efficient solutions may yield significant savings over the lifespan of the building.

Challenges and Future Outlook:

Despite the benefits and advancements in curtain wall technology, several challenges persist in the industry. One of the primary challenges is balancing cost considerations with performance requirements and design aesthetics. Striking the right balance often requires collaboration among architects, engineers, manufacturers, and contractors to achieve project objectives within budgetary constraints.

Moreover, the increasing complexity of building designs and regulatory requirements poses additional challenges for curtain wall procurement. Compliance with building codes, standards, and environmental regulations adds layers of complexity to the design and procurement process, potentially impacting project timelines and costs.

Looking ahead, the future of curtain wall pricing profiles is likely to be influenced by several emerging trends and innovations. These include:

- Integration of Smart Technologies: The integration of smart technologies, such as sensors, actuators, and adaptive facades, into curtain wall systems is expected to revolutionize building envelopes. Smart curtain walls can dynamically respond to environmental conditions, optimizing energy efficiency, occupant comfort, and indoor air quality.

- Advancements in Materials and Manufacturing: Continued advancements in materials science and manufacturing processes are driving the development of lightweight, durable, and sustainable curtain wall solutions. Innovations such as bio-based materials, 3D printing, and robotic fabrication have the potential to reshape the way curtain walls are designed, fabricated, and installed.

- Focus on Resilience and Disaster Mitigation: With the increasing frequency and severity of natural disasters, there is a growing emphasis on designing resilient building envelopes capable of withstanding extreme weather events, seismic activity, and other hazards. Curtain walls engineered for enhanced resilience and disaster mitigation may command premium pricing but offer long-term value in terms of occupant safety and building performance.

- Circular Economy Principles: The adoption of circular economy principles, which emphasize resource efficiency, waste reduction, and product lifecycle management, is gaining traction in the construction industry. Curtain wall manufacturers are exploring innovative strategies for recycling and repurposing materials, minimizing environmental impact, and maximizing resource utilization throughout the product lifecycle.

Mitigating Risks and Maximizing Opportunities:

Effectively managing risks and capitalizing on opportunities are integral to successful curtain wall procurement. Here are some strategies to consider:

- Risk Management: Identify potential risks early in the project lifecycle and develop mitigation strategies to address them. Risks related to cost overruns, schedule delays, quality issues, and regulatory compliance should be carefully assessed and managed through proactive planning, contingency measures, and effective communication among project stakeholders.

- Supplier and Contractor Selection: Choosing the right suppliers and contractors is paramount to the success of curtain wall projects. Conduct thorough due diligence to evaluate the reputation, experience, and track record of potential suppliers and contractors. Prioritize vendors with a proven history of delivering high-quality products and services within budget and on schedule.

- Contractual Agreements: Establish clear contractual agreements that outline project specifications, deliverables, timelines, and payment terms. Ensure that contracts include provisions for quality assurance, performance guarantees, dispute resolution mechanisms, and change management processes to mitigate potential conflicts and disputes throughout the project lifecycle.

- Value-Added Services: Explore value-added services offered by suppliers and contractors, such as design assistance, engineering support, mock-up testing, and post-installation maintenance programs. Leveraging these services can enhance project outcomes, streamline workflow, and minimize the risk of costly errors or rework during construction.

- Continuous Improvement: Foster a culture of continuous improvement by soliciting feedback from project stakeholders, conducting post-project evaluations, and implementing lessons learned to inform future procurement decisions. Embrace innovation and explore opportunities to leverage emerging technologies, materials, and construction methods to optimize curtain wall performance and cost-effectiveness.

Market Dynamics and Competitive Landscape:

Understanding market dynamics and the competitive landscape is crucial for effective curtain wall procurement. The curtain wall industry is influenced by various factors, including economic conditions, construction activity, technological advancements, and regulatory changes. Market trends such as urbanization, population growth, and increasing demand for high-performance buildings shape the demand for curtain wall systems.

Moreover, the competitive landscape of the curtain wall industry is characterized by a diverse array of suppliers, manufacturers, and contractors offering a wide range of products and services. Key players in the market compete on factors such as product quality, innovation, pricing, delivery times, and customer service. Collaboration with reputable and reliable partners can enhance project outcomes and mitigate risks associated with procurement.

Regulatory Compliance and Standards:

Compliance with building codes, standards, and regulations is a critical consideration in curtain wall procurement. Curtain wall systems must meet stringent requirements related to structural integrity, fire safety, energy efficiency, and environmental sustainability. Depending on the project location and building type, compliance with local, national, and international standards may be required.

Staying abreast of evolving regulatory requirements and industry standards is essential for ensuring the legality, safety, and performance of curtain wall systems. Working with experienced architects, engineers, and consultants can help navigate the complex landscape of regulatory compliance and streamline the procurement process.

Project Specific Considerations:

In addition to broader market dynamics and regulatory compliance, it’s essential to consider project-specific factors that can impact curtain wall procurement. These include:

- Site Conditions: Site-specific factors such as location, climate, terrain, and proximity to other structures can influence the design and performance requirements of curtain wall systems. For example, buildings located in high-wind or seismic zones may require robust curtain wall designs to withstand extreme weather conditions and seismic activity.

- Architectural Vision: Aligning curtain wall design with the architectural vision and aesthetic goals of the project is paramount. Customization options such as color, texture, transparency, and shape allow architects to create unique and visually striking facades that complement the overall design concept and enhance the building’s identity.

- Building Functionality: Consideration should be given to the functional requirements of the building and its occupants. Factors such as natural daylighting, views, privacy, thermal comfort, and acoustics can influence the selection and configuration of curtain wall systems to optimize indoor environmental quality and occupant satisfaction.

- Sustainability Goals: Many projects today prioritize sustainability and seek to minimize environmental impact through energy-efficient design, renewable materials, and green building certifications such as LEED (Leadership in Energy and Environmental Design). Curtain wall procurement presents an opportunity to incorporate sustainable design principles and achieve desired sustainability goals.

- Budget and Schedule Constraints: Balancing project budget and schedule constraints with performance and quality objectives is a common challenge in curtain wall procurement. Early collaboration among project stakeholders, value engineering exercises, and careful cost estimation are essential for managing costs and ensuring timely project delivery.

Post-Installation Considerations and Maintenance:

Once the curtain wall system is installed, ongoing maintenance and upkeep are essential to ensure its long-term performance and durability. Regular inspections, cleaning, and maintenance routines should be established to identify and address any issues promptly. This proactive approach can help prevent minor issues from escalating into costly repairs or replacements.

Routine maintenance tasks may include:

- Inspections: Regular inspections should be conducted to check for signs of damage, wear and tear, water infiltration, and structural integrity. Inspections should be carried out by qualified professionals familiar with curtain wall systems to identify potential issues early on.

- Cleaning: Cleaning the exterior surface of the curtain wall is necessary to maintain its appearance and prevent the buildup of dirt, debris, and pollutants. Depending on the location and environmental conditions, cleaning may be required on a periodic basis using appropriate cleaning agents and equipment.

- Sealant Inspection and Replacement: Sealants play a critical role in preventing water infiltration and maintaining the integrity of the curtain wall system. Inspecting sealant joints for signs of deterioration and replacing them as needed can help prevent water damage and ensure the long-term performance of the curtain wall.

- Hardware and Component Maintenance: Components such as hinges, gaskets, fasteners, and hardware should be inspected regularly to ensure proper functioning. Lubrication, adjustment, and replacement of worn or damaged components may be necessary to maintain optimal performance and functionality.

- Structural Integrity: Monitoring the structural integrity of the curtain wall system is essential to identify any signs of movement, deflection, or stress that could compromise its stability and safety. Structural assessments should be conducted periodically to assess the condition of load-bearing elements and address any issues promptly.

Conclusion:

In conclusion, post-installation considerations and ongoing maintenance are integral parts of curtain wall procurement that should not be overlooked. By implementing proactive maintenance routines and addressing issues promptly, stakeholders can prolong the lifespan of curtain wall systems, optimize their performance, and protect their investment in the built environment.

Collaboration among building owners, facility managers, maintenance personnel, and curtain wall contractors is essential for establishing effective maintenance protocols and ensuring the long-term success of curtain wall projects. By prioritizing maintenance and investing in regular upkeep, stakeholders can preserve the aesthetic appeal, functionality, and durability of curtain wall systems for years to come.

Leave A Comment