Difference between unitized and stick Curtain wall

Curtain walls have become a defining feature in modern architecture, seamlessly blending aesthetics and functionality to create impressive façades. Architects and designers often have a choice between two popular curtain wall systems: unitized and stick curtain walls. Each system has its unique characteristics, advantages, and drawbacks, catering to various project requirements. In this article, we will delve into the differences between unitized and stick curtain walls, shedding light on their construction, benefits, and considerations.

Unitized Curtain Walls: Seamless Integration and Efficiency

Unitized curtain walls are a contemporary approach to façade construction that involve assembling large pre-fabricated panels, or units, in a controlled factory environment before transporting and installing them on site. These panels typically comprise the glass, framing, and any necessary insulation, and are connected to the building structure using a system of anchors and brackets.

Advantages:

- Efficiency: The primary advantage of unitized curtain walls lies in their efficiency. Since these panels are manufactured off-site, the construction process becomes quicker and less dependent on weather conditions. This can significantly reduce project timelines, making it ideal for projects with tight schedules.

- Quality Control: Factory production ensures a higher level of quality control. The standardized manufacturing process results in consistent quality across all panels, reducing the likelihood of on-site errors and defects.

- Minimized Disruption: The assembly of unitized panels on-site is less disruptive to building occupants and the surrounding environment. This makes it an attractive option for projects in densely populated areas or those requiring minimal interruption to regular activities.

Considerations:

- Transport and Handling: Due to their pre-assembled nature, unitized panels can be large and heavy, requiring careful handling and specialized transportation.

- Design Flexibility: While unitized curtain walls offer a good degree of design flexibility, the factory production process might limit customization options compared to stick curtain walls.

Stick Curtain Walls: Versatility and Customization

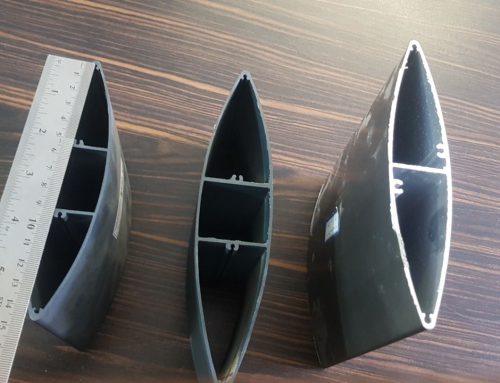

Stick curtain walls, in contrast, involve the assembly of individual components (sticks) on-site. These components include vertical mullions and horizontal rails, along with glass panels and insulation, which are assembled piece by piece.

Advantages:

- Customization: Stick curtain walls offer a higher degree of customization and adaptability to complex architectural designs. Each component is assembled on-site, allowing for adjustments and modifications as needed.

- Design Variability: Architects have greater design variability with stick curtain walls, enabling them to achieve unique visual effects and intricate detailing.

- Easier Replacement: If a particular component of the curtain wall needs replacement or maintenance, stick systems often allow for easier and more localized repairs.

Considerations:

- On-Site Time: The on-site assembly process of stick curtain walls is more time-consuming than unitized systems. This can extend project timelines, especially if weather conditions are unfavorable.

- Labor and Skill: Stick systems require skilled labor for assembly, which can increase labor costs. Additionally, the need for more on-site work might lead to disruptions during construction.

- Quality Control: Assembling components on-site can introduce a higher chance of errors and inconsistencies, necessitating vigilant quality control measures.

Choosing the Right System for Your Project

The choice between unitized and stick curtain walls ultimately depends on project-specific factors such as budget, timeline, design complexity, and desired customization. Both systems offer unique advantages and challenges, and architects must carefully weigh these aspects to determine which system aligns best with their project goals.

Installation and Maintenance

The installation process for unitized and stick curtain walls varies significantly, impacting project timelines and coordination efforts. Unitized systems, being pre-fabricated off-site, arrive at the construction site as complete panels ready for installation. This process requires less on-site labor and can progress even in adverse weather conditions, minimizing delays. The installation of unitized systems is also more predictable, as the panels are manufactured to precise specifications.

On the other hand, stick curtain walls involve on-site assembly of individual components. This process demands skilled labor and meticulous attention to detail to ensure accurate alignment and proper sealing. However, stick systems offer the advantage of easier transportation of components to the site, reducing the risk of damage during transit.

Maintenance considerations also influence the choice between these systems. Unitized curtain walls, with their factory-built panels, may be easier to maintain and repair due to their consistent quality. However, if a single panel requires replacement, it might be more challenging to match the existing unit’s appearance.

Stick curtain walls, despite potentially being more susceptible to quality inconsistencies, offer the advantage of easier component replacement. If one section of the curtain wall sustains damage, it can often be replaced without disrupting the entire system.

Cost Implications

Both unitized and stick curtain wall systems come with cost implications that architects and project managers need to consider. Unitized systems tend to have higher upfront costs due to the factory fabrication process and the need for specialized transportation. However, the potential for quicker installation and reduced on-site labor expenses can offset some of these initial costs.

Stick curtain walls, while potentially more cost-effective in terms of manufacturing and transportation, can accrue higher on-site labor costs due to the need for skilled assembly and a longer installation timeline.

The choice between these systems should be based on a comprehensive cost-benefit analysis that takes into account factors like project size, timeline, labor availability, and long-term maintenance expenses.

Project Considerations

Architects and designers must carefully evaluate project-specific factors when deciding between unitized and stick curtain wall systems:

- Project Scale and Timeline: For larger projects with tight schedules, unitized systems may offer time-saving advantages. Smaller projects with more flexible timelines might find stick systems suitable.

- Design Complexity: Intricate architectural designs often benefit from stick systems that allow for on-site adjustments and customization. Unitized systems might be better suited for projects with simpler aesthetics.

- Budget Constraints: Available budget plays a crucial role. While unitized systems have higher upfront costs, they might save money in the long run due to reduced labor and quicker installation.

- Location and Climate: Climate conditions can impact the feasibility of on-site assembly. Unitized systems might be favored in regions with inclement weather, as they can be fabricated indoors and transported to the site.

- Maintenance Accessibility: Consider the ease of future maintenance and repairs. Stick systems may allow for targeted repairs, while unitized systems might require more extensive panel replacement.

In conclusion, the choice between unitized and stick curtain walls requires a careful evaluation of various factors, each impacting project timelines, aesthetics, costs, and long-term maintenance. Architects and designers should collaborate closely with engineers, contractors, and other stakeholders to make an informed decision that aligns with the project’s goals and requirements. Ultimately, selecting the appropriate curtain wall system can contribute to the overall success and aesthetic appeal of the architectural endeavor.

Leave A Comment