Curtain wall details with dimensions typical design

Introduction:

Curtain walls are a popular architectural feature in modern buildings, providing numerous benefits such as natural light, thermal insulation, and aesthetic appeal. These non-structural façade systems consist of lightweight materials and are typically installed on the exterior of buildings to create a seamless and visually appealing envelope. In this article, we will delve into the typical design and dimensions of curtain walls, shedding light on their key features and considerations.

-

Frame Design:

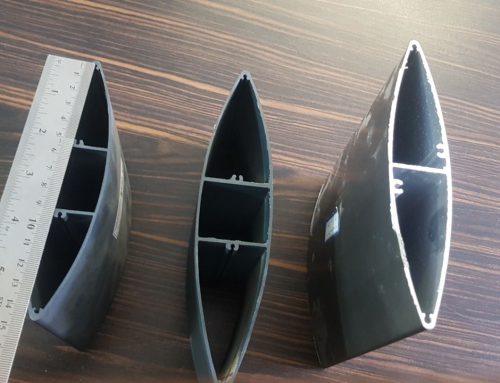

Curtain walls are primarily constructed using aluminum frames due to their lightweight nature, durability, and resistance to corrosion. The frame design can vary depending on the specific project requirements and desired aesthetics. Common frame designs include:

- Stick System: This design involves assembling individual mullions (vertical members) and transoms (horizontal members) on-site, allowing for greater flexibility in customizing dimensions and shapes.

- Unitized System: In this approach, the curtain wall is divided into pre-fabricated units that are assembled and glazed off-site. Unitized systems offer faster installation times and improved quality control.

-

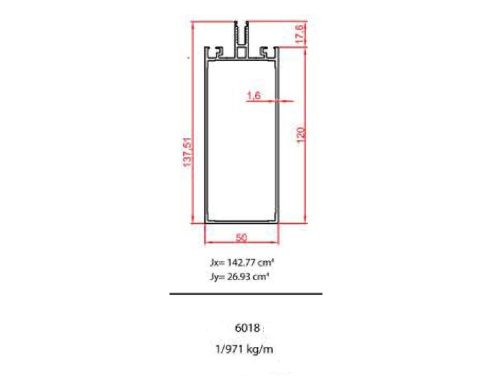

Mullion and Transom Dimensions:

Mullions and transoms form the structural framework of a curtain wall. Their dimensions are determined by factors such as wind load, dead load, and glazing requirements. Typical dimensions for mullions range from 100mm to 300mm (4″ to 12″) in width and 150mm to 600mm (6″ to 24″) in depth. Transom dimensions are usually similar to or slightly smaller than mullions.

-

Glazing Options:

Glazing plays a crucial role in curtain wall design, contributing to thermal performance, sound insulation, and visual aesthetics. Common glazing options include:

- Single Glass: Utilized in applications where thermal insulation is not a primary concern, single glass panels are typically 6mm to 12mm (1/4″ to 1/2″) thick.

- Double Glazed: This type of glazing consists of two layers of glass separated by an air or gas-filled cavity. It provides better thermal insulation and sound reduction. Typical thickness ranges from 24mm to 32mm (1″ to 1-1/4″).

- Triple Glazed: Triple glazing offers even higher thermal insulation and sound reduction. It comprises three layers of glass with two insulating cavities. Typical thicknesses range from 36mm to 50mm (1-1/2″ to 2″).

-

Anchoring and Installation:

Curtain walls are anchored to the building structure using various methods such as pressure plates, cover caps, or structural silicone glazing. The installation process should consider factors like weatherproofing, thermal expansion, and seismic requirements.

-

Integrated Components:

Curtain walls can incorporate additional features and components, including:

- Sunshades and Louvers: Used for solar control and glare reduction, these elements are typically mounted on the exterior of the curtain wall.

- Ventilation and HVAC: Integration of operable windows or vents allows for natural ventilation, while HVAC systems can be integrated into the curtain wall design.

-

Thermal Performance:

Thermal performance is a critical consideration in curtain wall design, as it directly affects energy efficiency and occupant comfort. To enhance thermal insulation, curtain walls can incorporate thermal breaks within the aluminum frames, which minimize heat transfer between the interior and exterior. Additionally, low-emissivity (low-E) coatings can be applied to the glass to reduce heat gain or loss.

-

Acoustic Performance:

In buildings located in noisy environments or near busy streets, acoustic performance becomes crucial. Curtain walls can be designed to provide sound insulation by incorporating laminated glass with acoustic interlayers or by using double or triple glazing with varying thicknesses to block unwanted noise.

-

Fire Safety:

Fire safety is a paramount consideration in building design. Curtain walls should comply with local fire codes and regulations. Fire-resistant glazing or fire-resistant coatings can be incorporated into the curtain wall system to maintain the integrity of the building envelope and prevent the spread of fire.

-

Testing and Certification:

Curtain walls undergo rigorous testing to ensure they meet industry standards and performance requirements. Testing includes assessments for water penetration resistance, air infiltration, structural integrity, and thermal performance. Manufacturers often provide certifications or ratings indicating the curtain wall’s performance capabilities, allowing architects and engineers to make informed decisions.

-

Maintenance and Repair:

Proper maintenance and periodic inspection are essential for preserving the performance and appearance of curtain walls over time. Routine cleaning, checking for damaged gaskets or seals, and addressing any issues promptly are necessary to ensure the longevity of the system. Access for maintenance, such as anchor points or platforms, should be considered during the design phase.

-

Sustainability Considerations:

Sustainable design practices are increasingly important in modern architecture. Curtain walls can contribute to energy efficiency and sustainability by maximizing natural daylight, reducing reliance on artificial lighting, and incorporating high-performance glazing. Additionally, curtain walls can accommodate photovoltaic panels or solar shading devices to harness renewable energy and optimize thermal comfort.

Conclusion:

Curtain walls are sophisticated architectural elements that provide a range of benefits, from aesthetic appeal to energy efficiency. Understanding the typical design and dimensions of curtain walls, as well as considering factors such as thermal performance, acoustic insulation, fire safety, and sustainability, allows professionals to create functional, visually pleasing, and environmentally responsible building envelopes. By carefully selecting materials, incorporating advanced glazing options, and adhering to industry standards, curtain walls can meet the diverse needs of modern construction projects, enhancing both the form and function of the built environment.

Leave A Comment