Advancing Aluminum Manufacturing Technology

Aluminum, known for its exceptional combination of strength, lightweight properties, and corrosion resistance, has played a pivotal role in modern industry and technology. From aerospace and automotive applications to electronics and packaging, aluminum’s versatility has made it a cornerstone material. However, the relentless pursuit of innovation has given rise to advanced aluminum manufacturing technologies, transforming the way this metal is processed, shaped, and utilized.

1. Additive Manufacturing and 3D Printing

One of the most revolutionary advancements in aluminum manufacturing is the integration of additive manufacturing, commonly known as 3D printing. This cutting-edge technique enables the creation of intricate and complex aluminum structures that were once unfeasible with traditional methods. By layering aluminum powder and selectively melting it with lasers, 3D printing allows engineers to fabricate lightweight, high-strength components with minimal material wastage. Industries like aerospace are embracing this technology for creating intricate parts that reduce weight and enhance performance.

2. High-Strength Alloys and Nanotechnology

Advancements in metallurgy and nanotechnology have enabled the development of high-strength aluminum alloys with enhanced mechanical properties. By incorporating nanoparticles into the alloy matrix, manufacturers can improve strength, hardness, and thermal stability. These advanced alloys find applications in high-stress environments such as aerospace and automotive manufacturing, where lightweight yet durable materials are essential for optimal performance and fuel efficiency.

3. Smart Manufacturing and Automation

The rise of Industry 4.0 has spurred the integration of smart manufacturing and automation in aluminum production facilities. Robotics, artificial intelligence, and the Internet of Things (IoT) are being harnessed to streamline production processes, enhance quality control, and minimize human error. These technologies ensure consistent output, reduce downtime, and optimize energy consumption, ultimately leading to higher productivity and cost savings.

4. Eco-Friendly and Sustainable Practices

In an era of increasing environmental consciousness, aluminum manufacturers are striving to adopt more sustainable practices. Advanced technologies such as “green” smelting processes that minimize energy consumption and carbon emissions are being explored. Additionally, recycling techniques for aluminum are being refined, allowing the metal to be recycled repeatedly without losing its properties. This not only conserves resources but also reduces the carbon footprint associated with aluminum production.

5. Digital Twinning and Simulation

Digital twinning, a concept where a virtual replica of a physical asset is created and monitored in real-time, is transforming aluminum manufacturing. Through sophisticated simulations and real-time monitoring, manufacturers can predict equipment maintenance needs, optimize production processes, and ensure quality control. This technology minimizes downtime, reduces costly errors, and maximizes overall efficiency.

6. Advanced Surface Treatments

Surface treatments play a vital role in enhancing the durability, aesthetics, and corrosion resistance of aluminum products. Cutting-edge technologies such as plasma electrolytic oxidation (PEO) and anodizing are being used to create protective coatings with superior properties. These coatings not only extend the lifespan of aluminum components but also open new avenues for innovative designs and applications.

7. Joining Techniques and Hybrid Materials:

As aluminum components become more intricate and diverse, joining techniques have become a critical aspect of advanced manufacturing. Traditional methods like welding, brazing, and adhesive bonding are being combined with emerging technologies such as friction stir welding (FSW) and laser-based processes. These techniques offer improved joint strength, reduced distortion, and enhanced precision. Additionally, the rise of hybrid materials, where aluminum is combined with other materials like composites, further expands the realm of possibilities for designing lightweight yet robust structures.

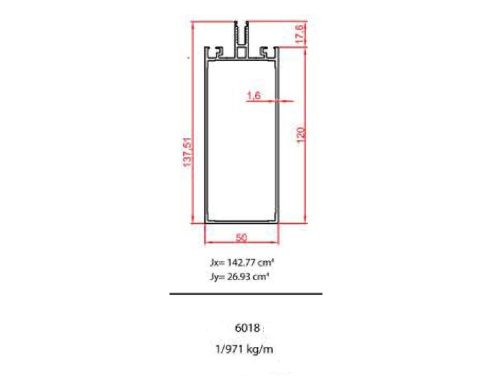

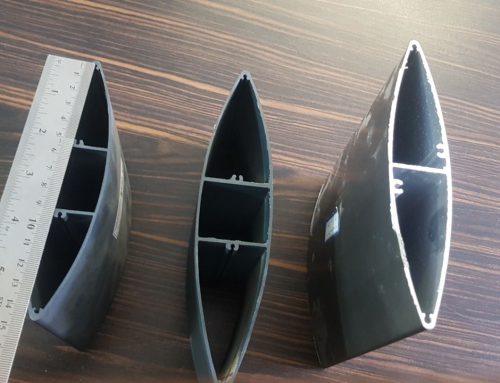

8. Energy-Efficient Extrusion:

Extrusion is a fundamental process in aluminum manufacturing, used to create profiles of various shapes and sizes. Advanced extrusion technologies are focusing on energy efficiency and precision. Warm extrusion, for instance, involves heating the aluminum billet to a temperature below its melting point, reducing the extrusion force required and enhancing the quality of the final product. These innovations not only conserve energy but also allow for the production of intricate profiles with tight tolerances.

9. Advanced Machining Techniques:

Aluminum’s exceptional combination of lightweight and strength makes it a popular choice for precision components. Advanced machining techniques, such as high-speed machining and cryogenic machining, are enabling manufacturers to achieve greater precision, faster production rates, and improved surface finishes. These techniques are especially valuable in industries where complex aluminum parts play a crucial role, such as aerospace and medical device manufacturing.

All-focus

10. Collaborative Research and Open Innovation:

The rapid pace of technological advancement in aluminum manufacturing has created a need for collaboration and open innovation. Industry leaders, research institutions, and technology providers are coming together to share knowledge, resources, and insights. This collaborative approach accelerates the development and adoption of new technologies, allowing the industry to stay at the forefront of innovation.

11. Regulatory and Safety Considerations:

As aluminum manufacturing technologies evolve, it’s important to address regulatory and safety considerations. Innovations like additive manufacturing might introduce new challenges in terms of material quality, structural integrity, and certification. Regulatory bodies and industry standards organizations are working closely with manufacturers to ensure that these advancements meet stringent safety and quality requirements.

The Road Ahead:

The journey of advancing aluminum manufacturing technology is a dynamic and ongoing process. As industries continue to demand higher performance, increased sustainability, and innovative designs, the aluminum sector must remain vigilant in its pursuit of excellence. From aerospace and automotive to electronics and packaging, the applications of advanced aluminum manufacturing are boundless.

By embracing additive manufacturing, high-strength alloys, smart manufacturing, sustainability practices, and other groundbreaking technologies, aluminum manufacturers are contributing to a future where this versatile metal continues to play a pivotal role. As research and development efforts persist, we can anticipate even more remarkable breakthroughs that will redefine the capabilities of aluminum and reshape entire industries.

The aluminum industry is undergoing a remarkable transformation, driven by advancements in manufacturing technologies that are pushing the boundaries of what’s possible with this versatile metal. From 3D printing and high-strength alloys to smart manufacturing and sustainable practices, these innovations are revolutionizing the way aluminum is produced, processed, and utilized across various sectors.

As these technologies continue to evolve and mature, we can expect to see even more groundbreaking applications emerge. Whether it’s the creation of lighter and more fuel-efficient vehicles, more efficient aerospace structures, or sustainable packaging solutions, advanced aluminum manufacturing technology is undoubtedly shaping the future of industries reliant on light metals. As the journey of innovation continues, collaboration between researchers, manufacturers, and policymakers will be crucial in unlocking the full potential of aluminum and ushering in a new era of materials engineering.

In conclusion, the advancement of aluminum manufacturing technology represents a transformative chapter in the history of light metals. With each innovation, we inch closer to realizing the full potential of aluminum, unlocking opportunities for greater efficiency, sustainability, and performance across diverse sectors. As the collaboration between science, engineering, and industry deepens, the horizon for aluminum’s possibilities continues to expand, promising a future where this metal’s potential knows no bounds.

Leave A Comment